The Brando’s Mission

A non-profit and a luxury resort collaborate for greater good

The Brando is singularly focused on one mission: zero carbon. Sustainability on the atoll is a partnership—if the Tetiaroa Society is the guardian of the atoll, then The Brando is the vehicle to showcase the work of the Society with the world.

Every action, creation, and narrative aims to illuminate the uniqueness of this location. The commitment ensures that while the impact of a visit lingers in the memories of guests, it leaves no trace on the atoll itself, embodying a profound respect for the environment and Polynesian heritage.

TETIAROA SOCIETY

The pioneers of our sustainability efforts

The EcoStation on Onetahi motu stands as a beacon of sustainability, where international scientists converge to safeguard terrestrial and marine biodiversity and nurture the vibrant Polynesian culture. Recognized globally, these pioneering efforts serve as a blueprint for luxury tourism with a conscience. Highlights of the Tetiaroa Society‘s initiatives below demonstrate how they are integrated into daily operations to dramatically diminish the carbon footprint of The Brando.

Sustainability developments

Renewable Energy

The resort features two varieties of solar panels. Positioned on Tetiaroa’s airstrip, over 4,700 photovoltaic panels meet 60% of the energy requirements.

Surplus energy is conserved in lithium batteries, ensuring nocturnal power supply for the island. These solar batteries, crafted predominantly from recyclable materials, boast a service life extending through thousands of deep discharge cycles.

Campus-wide LEED Platinum Certification

The Brando holds the distinction of being the first resort worldwide to be awarded the LEED Platinum Certification, the highest commendation by the U.S. Green Building Council. This certification is comprehensive, encompassing every structure within the resort’s domain, from energy facilities to ancillary buildings, all adhering to stringent sustainability criteria.

The resort’s design is meticulously planned to minimize resource use, eliminate waste, mitigate environmental impact, and optimize lifecycle efficiency, thus enhancing guest comfort while significantly lowering ecological footprints. These efforts are part of the criteria for LEED Certification, demonstrating a commitment to environmental stewardship without sacrificing luxury.

LEED platinum qualifications

Location and Transportation

- Sensitive Land Protection

- Bicycle Facilities

- Electric Vehicles

Sustainable Sites

- Protect or Restore Habitat

- Open Space Rainwater

- Management Light

- Pollution Reduction

Materials and Resources

- Storage and Collection of Recyclables

- Sourcing of Raw Materials

- Material Ingredients

- Construction and Demolition Waste Management

Energy and Atmosphere

- Optimize Energy Performance

- Renewable Energy

- Enhanced Refrigerant Management

Indoor Environmental Quality

- Thermal Comfort

- Interior Lighting

- Daylight

- Quality Views

- Acoustic Performance

Water Efficiency

- Outdoor Water Use Reduction

- Indoor Water Use Reduction

- Optimize Process Water Use

- Water Metering

Carbon Neutral

The aim on Tetiaroa is to deliver a carbon-neutral experience to each guest. While The Brando is on the cusp of this objective, certain strides are yet to be made to fulfill this ambitious target. The main focus areas include energy generation and minimizing the carbon footprint of transportation to and from the island. Insights into the full range of environmental initiatives can be gained through the Green Tour, an educational excursion offered to guests.

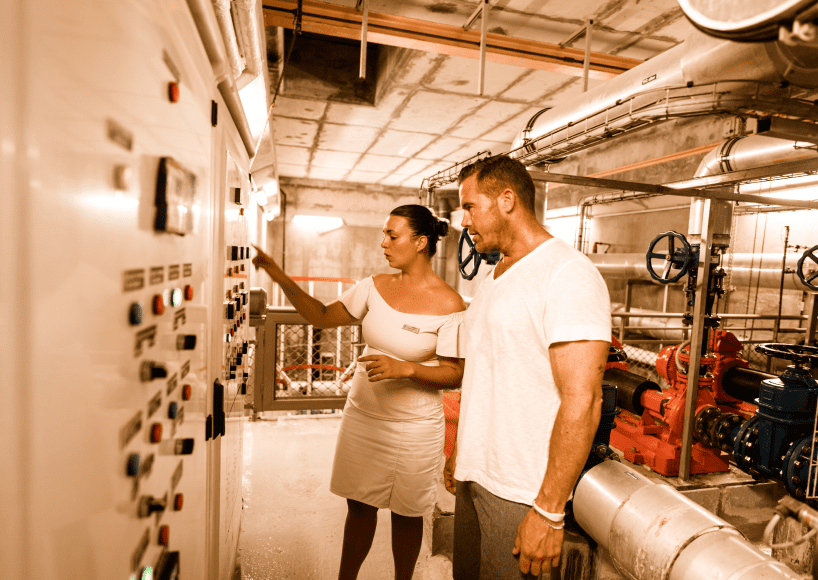

Sea Water Air Conditioning (SWAC)

Inaugurated in 2014, the Sea Water Air Conditioning (SWAC) system taps into the ocean’s depths to cool the resort’s structures with minimal energy consumption. Ocean water is siphoned ashore by the natural pressure of the deep sea, flowing through a titanium heat exchanger before it is returned to the ocean, causing no harm to the environment.

This innovative system slashes the energy consumption for air conditioning by up to 90% compared to traditional methods.

Organic Garden

At The Brando, food waste undergoes a rapid transformation into compost, achieved within 24 hours through advanced eco digesters. These systems provide vital nutrients that greatly enhance the sandy soil, facilitating the cultivation of an array of fruits and vegetables on the premises. The bounty harvested is incorporated daily into the offerings of the resort’s restaurants and bars.

The resort’s garden is an abundant source of various produce, flourishing in the island’s unique blend of sun, sand, and coral. It boasts an array of crops including vanilla, kumquat, papaya, bananas, limes, a selection of aromatic herbs, pomegranates, tomatoes, cucumbers, eggplant, zucchini, green onions, among others, all nurtured within this radiant ecosystem.

Water & Conservation

On the atoll of Tetiaroa, amidst the vast South Pacific, water is not merely a resource but a treasured asset. The atoll’s approach includes collecting and desalinating seawater, and employing reverse osmosis to supply potable water. Rainwater is harvested from the aquifer and rooftops, finding use in swimming pools, sanitation, and laundry. Furthermore, wastewater, once treated at sewage facilities, is repurposed for irrigation, embodying a full-cycle water management system that respects and utilizes every drop.

The Sorting Center

The Sorting Center serves as a pivotal hub within the resort, transforming waste into valuable, reusable commodities.

Here, food waste is rapidly processed into organic compost, which then enriches the organic gardens. Glass materials are refined and repurposed by a local Tahitian company, combined with concrete for enhanced durability. Aluminum cans embark on a circular journey, being sold and reprocessed into raw aluminum. Additionally, used cooking oils are collected and distributed to companies specializing in the conversion of such materials into biofuel.

Wastewater Treatment

All wastewater is carried to the treatment plant where it is filtered and treated by aquatic tropical plants. Once purified, the water is stored and reused for irrigation.

Building Connections Among Communities

Tetiaroa is a community of individuals from a multitude of sectors – partners, environmental advocates, researchers, and academic bodies – who come together in the spirit of cooperation. There is a collective effort to embolden these partners to become champions of sustainability in their daily routines, sharing effective strategies and involving them in environmental events such as World Clean Up Day, World Plastic Bag Free Day, and Earth Hour.

Moreover, alliances with entities like the Tetiaroa Society, dedicated to marine conservation research, and Te Mana O Te Moana, focusing on sea turtle education, as well as engagements with social initiatives like Saga that aid underprivileged youth, cultivate a communal bond. These joint ventures are the threads that weave together a unified commitment to sustainability.

We Care

We are proud to unveil our new CSR brand identity: We Care

“We Care” encapsulates the enduring commitments and values celebrated year-round.

The emblem, a fusion of a coral branch and a monstera leaf forming a heart, illustrates the dedication to safeguarding nature and the sea, which are integral to Polynesian heritage. This emblem radiates the warmth characteristic of Polynesian culture, pulsating with love for their homeland, known as ‘fenua.’ Moreover, the heart signifies the genuine concern for the welfare of the team members and the wider community.

A simple message: protection, respect, and steadfast dedication.

We Care for Environment

We conserve our resources through the smart use of infrastructure and the knowledge and care of our teams.

We Care for Nature & Culture

We take action to promote the biodiversity of our fenua and to enhance our cultural heritage by sharing our Polynesian traditions.

We Care for People

We are committed to the well-being of our staff, and contribute to the local community: schools, NGOs and associations.

In keeping with the vision of our parent company, Pacific Beachcomber S. C., our mission is to provide exemplary, authentic, and enriching travel experiences for our guests that are environmentally sensitive, sustainable, and that celebrate Polynesian cultural heritage.

We believe in the power of travel to make the world a better place, protecting our natural and cultural heritage for future generations through exploration, discovery, education and conservation.